The manufacturing landscape has transformed over the past few decades, with high-precision machining emerging as a game-changer. Unlike traditional fabrication methods, which often rely on manual or semi-automated processes, high-precision machining leverages cutting-edge technology to achieve unparalleled accuracy. This evolution has brought profound improvements in efficiency, product quality, and innovation. Below, we’ll explore the key differences between modern high-precision machining and traditional fabrication methods, highlighting how businesses benefit from adopting advanced techniques.

Precision and Tolerance Capabilities

One of the most notable distinctions between modern high-precision machining and traditional fabrication is accuracy. High-precision machining operates within incredibly tight tolerances, often measured in microns. This capability ensures that even the most intricate components meet exact specifications. Traditional fabrication methods, while effective for many projects, can struggle to achieve similar precision due to reliance on hand tools or less sophisticated equipment.

One of the most notable distinctions between modern high-precision machining and traditional fabrication is accuracy. High-precision machining operates within incredibly tight tolerances, often measured in microns. This capability ensures that even the most intricate components meet exact specifications. Traditional fabrication methods, while effective for many projects, can struggle to achieve similar precision due to reliance on hand tools or less sophisticated equipment.

For instance, industries like aerospace, medical device manufacturing, and semiconductors demand extreme precision for their parts. High-precision machining technology, such as CNC (computer numerical control) machines, ensures components align perfectly, reducing the need for secondary adjustments or rework. Traditional methods, by contrast, are more prone to human error or dimensional inconsistencies, which can compromise the final product.

Additionally, high-precision machining often includes automated measurement and quality checks throughout the production process. This ‘in-line’ verification ensures every unit meets the specified tolerances. Traditional methods typically rely on manual inspections, which may introduce inconsistencies or delays in production timelines.

Technology Integration and Automation

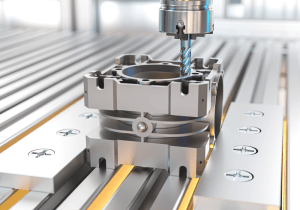

Another major difference lies in the integration of advanced technology and automation. High-precision machining relies heavily on computer-driven systems, such as CNC and CAD (computer-aided design), to control the manufacturing process. These technologies allow design engineers to create highly detailed digital blueprints that are then translated directly into machine instructions.

Automation plays a pivotal role in improving speed and consistency. CNC machines, for example, can run complex operations continuously with minimal human intervention, ensuring uniformity across large production volumes. Traditional fabrication methods, however, often depend on manual labor or less automated machinery, which introduces more variability and slows down production.

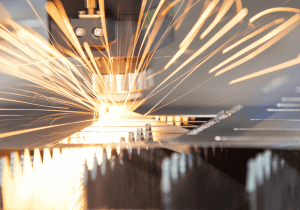

High-precision machining also incorporates tools such as 5-axis machining centers and laser cutters, which can handle complex geometries with incredible accuracy. By automating complex tasks, manufacturers can produce intricate components that would be nearly impossible to create using traditional methods. The result is heightened efficiency and the ability to explore more innovative designs.

Material Versatility in Manufacturing

High-precision machining offers unparalleled flexibility when it comes to materials. Modern machines can work with a wide range of substances, including metals like titanium, aluminum, and stainless steel, as well as non-metals like plastics, ceramics, and composites. This versatility ensures that manufacturers can tailor their processes to meet the specific demands of each project.

Traditional fabrication methods also handle diverse materials, but they may not achieve the same level of accuracy or finish, especially when working with harder or more brittle materials. For example, using traditional techniques on high-strength alloys may lead to surface defects or uneven edges due to less refined tools or processes.

High-precision machines use advanced cutting tools, minimal heat generation, and sophisticated cooling systems to prevent material stress or damage during machining. These factors enable manufacturers to preserve the structural integrity of materials while achieving superior finishes, something that is often more challenging with conventional methods.

Production Speed and Efficiency

Time efficiency is a critical aspect where high-precision machining outperforms traditional methodologies. Advanced CNC machines can execute complex tasks like drilling, milling, and turning simultaneously, significantly reducing production times. Traditional fabrication methods, which may require multiple steps with different tools and machines, naturally take longer to produce the same results.

Time efficiency is a critical aspect where high-precision machining outperforms traditional methodologies. Advanced CNC machines can execute complex tasks like drilling, milling, and turning simultaneously, significantly reducing production times. Traditional fabrication methods, which may require multiple steps with different tools and machines, naturally take longer to produce the same results.

The ability to combine multiple operations into a single setup is a defining advantage of high-precision machining. For example, creating a multi-geometry component using traditional tools might involve separate tasks for cutting, welding, and polishing. High-precision machines can streamline these processes, reducing errors and boosting overall productivity.

Furthermore, high-precision machining supports rapid prototyping, allowing businesses to quickly test and refine their designs before mass production. The iterative nature of prototyping benefits greatly from the speed and consistency offered by modern machining, making it the preferred method for industries with tight deadlines or frequent product updates.

Customization and Adaptability

Modern high-precision machining excels in creating customized components tailored to unique client specifications. This adaptability is fueled by advanced programming capabilities that allow machines to produce one-off parts with the same accuracy and efficiency as mass-produced items. Whether the need is for ultra-thin components or intricate internal features, these systems can deliver.

Traditional fabrication methods are less suited to customization, especially for complex or small-scale projects. Manual adjustments or retrofitting tools can be time-intensive, adding costs and slowing production. High-precision machining eliminates these challenges through digital control and pre-programmed repeatability.

This adaptability also allows manufacturers to quickly pivot between designs, responding to evolving consumer demands or engineering improvements. It’s no surprise that industries relying on innovation, like automotive or medical technology, depend heavily on high-precision machining for their operations.

Environmental Impact and Waste Reduction

Sustainability is becoming increasingly important in modern manufacturing, and high-precision machining aligns well with this goal by minimizing material waste. Using CAD and CNC systems, manufacturers can optimize how raw materials are cut, drilled, or shaped to utilize every scrap efficiently. This precision not only saves costs but also reduces the environmental footprint of production.

Traditional fabrication methods often result in more waste, as they rely on less refined processes and may require additional raw materials to compensate for errors or inefficiencies. This surplus material usage can significantly increase production costs and environmental impact, especially in large-scale operations.

Another benefit of high-precision machining is its energy efficiency. Modern equipment is designed to consume less power while maintaining maximum output, further supporting greener manufacturing practices.

Maintenance and Longevity of Tools

Durability and longevity of production tools are other factors where high-precision machining holds the edge over traditional fabrication methods. Advanced machinery is engineered for long-term use, with built-in maintenance alerts and diagnostic tools to prevent wear and tear. This proactive upkeep ensures consistent results and minimal downtime.

Traditional tools often require frequent sharpening, replacement, or manual alignment due to their less sophisticated design. Over time, these recurring maintenance needs can lead to increased costs and interruptions in production schedules. High-precision machines, with their automated calibration and self-diagnostic features, eliminate much of this inefficiency.

Additionally, high-precision setups are designed to remain consistent even after extensive use, ensuring that product quality does not deteriorate over time. This reliability makes high-precision machining an essential investment for companies aiming to deliver consistently high-quality results.

High-precision machining has revolutionized the manufacturing industry, delivering unmatched accuracy, efficiency, and versatility compared to traditional fabrication methods. With its ability to handle complex geometries, work across diverse materials, and enable rapid, sustainable production, it’s no wonder that industries from aerospace to automotive are increasingly adopting these advanced processes. While traditional methods still have their place in certain applications, the future of manufacturing clearly belongs to high-precision machining. Businesses looking to stay competitive would do well to explore the benefits that this cutting-edge technology can bring to their operations.