Creating a new product is an exciting yet challenging process, especially in the industrial manufacturing and metal fabrication industries. Whether it’s a custom piece of machinery, a metal component, or a large-scale assembly, translating an idea into a tangible finished product requires precision, planning, and efficiency. Enter product prototyping, a game-changing process that helps businesses save both time and money while improving the overall quality of their products.

This blog will explore the ins and outs of product prototyping, its role in identifying design flaws, reducing waste, and enhancing the final product. Additionally, we’ll look at real-world examples and provide actionable tips to help you implement effective prototyping methods in your operations.

Understanding Product Prototyping

What is Product Prototyping?

At its core, product prototyping is the process of creating a preliminary model or sample of a product to test its design and functionality before full-scale production. It acts as a bridge between the concept or design phase and the production phase, providing a physical representation of the product.

For industrial manufacturing and metal fabrication, prototyping often involves creating a scaled-down or full-sized representation of metal parts, tools, or assemblies. Whether these are created with advanced computer-aided design (CAD) software or 3D printing machines, prototypes allow stakeholders to assess various aspects of the product, such as its performance, durability, and aesthetic appeal.

Types of Prototypes

Product prototypes fall into several categories depending on the purpose they serve:

- Conceptual Prototypes

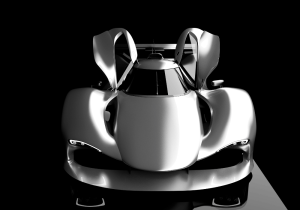

These are basic models used to conceptualize the product’s design. They don’t focus on functionality, but often give an accurate visual representation.

Functional Prototypes

Functional Prototypes

This type of prototype tests the performance, mechanics, and usability of the product. For example, an aluminum component can be prototyped to assess its strength and thermal properties.

- Production Prototypes

These prototypes closely resemble the final product and are used to fine-tune manufacturing processes, making them ideal for metal fabrication industries.

Saving Time with Prototyping

Identifying Design Flaws Early

One of the greatest advantages of prototyping is its ability to spot potential design flaws before entering production. Imagine investing in the mass production of a metal bracket only to discover that the original design causes stress points to form under heavy loads. A prototype can highlight this issue early, enabling engineers to modify the design and avoid costly errors down the line.

Streamlining the Development Process

Prototyping brings clarity to the development process. By creating a tangible model, teams across engineering, design, and production departments can collaborate more effectively. This speeds up decision-making, reduces miscommunication, and ensures that by the time manufacturing begins, all stakeholders are aligned.

Saving Money with Prototyping

Reducing Material Waste

The cost of materials is a significant concern in metal fabrication, where materials like steel, aluminum, or copper don’t come cheap. Prototyping helps reduce waste by ensuring that design and production parameters are exact before large-scale manufacturing. For example, CNC machining a prototype allows engineers to optimize how to cut raw materials efficiently, preventing waste in the production process.

Minimizing Production Errors

Production errors can be extremely costly, especially in industries where precision is critical. A single dimensional error in a fabricated metal component can render an entire batch unusable. Prototypes help identify and resolve such problems early, saving businesses from costly rework, product recalls, or material losses.

Real-World Examples

Case Study 1: Customized Metal Brackets

A global leader in heavy machinery manufacturing faced challenges in creating a new line of reinforced metal brackets. Initial CAD simulations suggested the design was sound, but a small-batch prototype revealed weak points likely to fail under stress. Modifications were made before production, saving the company weeks of time and thousands of dollars in wasted materials.

Case Study 2: Welding Fixture Design

An industrial metal fabrication company leveraged prototyping to design complex welding fixtures. The prototype helped the team refine the fixture’s design, reducing welding time by 30 percent and ultimately ensuring consistent quality in the production line.

Best Practices for Effective Prototyping

Prioritize Functionality

While a product’s look and feel are important, functionality should take precedence when creating prototypes. This is especially critical in industries like industrial manufacturing, where performance is paramount.

Choose the Right Prototyping Method

Choose the Right Prototyping Method

The method you use for prototyping largely depends on your product and industry. For instance:

- Use 3D printing for quick, cost-effective prototypes of complex geometries.

- Opt for CNC machining when high levels of precision and material properties are required.

- Leverage virtual prototypes (digital simulations) for initial concept analysis.

Gather Diverse Input

Prototyping is a collaborative process. Seek input from all stakeholders, including designers, engineers, and production managers. Their collective expertise will lead to more efficient designs and fewer production challenges.

The long-term benefits of prototyping far outweigh the resources invested upfront. By identifying flaws early, reducing waste, and optimizing production, manufacturers can improve their bottom lines while delivering higher-quality products. Industrial manufacturing and metal fabrication industries have much to gain by incorporating prototyping into their workflows. Not only does it minimize risks, but it also fosters innovation by enabling businesses to experiment with new designs and materials.

If your team hasn’t yet adopted a robust prototyping practice, now might be the perfect time to start. Doing so will future-proof your processes, saving you both time and money in an increasingly competitive landscape.

Reach out to MBI Industrial Manufacturing to get your project started.

Choose the Right Prototyping Method

Choose the Right Prototyping Method